Top News

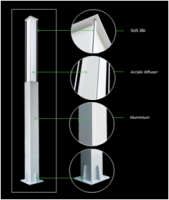

Mr. Nguyen Quan Chinh, Vice Chairman, People's Committee of Quang Tri Province came to visit the site of LED installation.

Making potable water from oil and gas production

In the midst of an intensifying global water crisis, scientists are reporting development of a more economical way to use one form of the "ice that burns" to turn very salty wastewater from fracking and other oil and gas production methods into water for drinking and irrigation.

The study on the method, which removes more than 90 percent of the salt, appears in the journal ACS Sustainable Chemistry & Engineering.

Yongkoo Seol and Jong-Ho Cha explain that salty wastewater is a byproduct of oil and gas production, including hydraulic fracturing, or fracking. These methods use water and produce as a byproduct almost 10 barrels of salty water for every barrel of oil. That water could help people in water-stressed regions. But it can't be desalinated economically with traditional methods. Seol and Cha knew that an alternative called "gas hydrate desalination" showed promise.

Making potable water from oil and gas production

A gas hydrate consists of only water and a gas such as methane, the stuff of natural gas. Thus, when hydrates form, salts and other impurities are left behind. When the hydrate breaks down, the gas and pure water are released. However, forming the gas hydrate used in desalination required costly chilling of the water to 28 degrees Fahrenheit. Seol and Cha sought to develop a less costly version of the method, which involves a variation on methane hydrates, chunks of ice retrieved from deep below the sea that burst into flame when brought to the surface.

They describe development and laboratory testing of a new type of gas hydrate desalination technique. They formed the hydrates from water and carbon dioxide with the gases cyclopentane and cyclohexane, which made the method work more efficiently. It removed more than 90 percent of the salt compared to 70 percent with the previous gas hydrate technique. And the process works at near-room temperature, reducing the need for chilling.

Sciencedaily.com

Source: tietkiemnangluong.com.vn

Newer articles

- Cooling Your Home This Summer with Energy Efficient Windows (09/07/2014)

- Clean energy for home grabs attention at Energy Fair (04/07/2014)

- Introduce energy labels (02/07/2014)

- Documents (28/06/2014)

- France helps Vietnam develop renewable energy (24/06/2014)

Older articles

- Technology uses micro-windmills to recharge cell phones (11/06/2014)

- £14m boost for future UK energy research (07/06/2014)

- Prospects of applying Swedish “green” technologies in Vietnam (06/06/2014)

- Rain used to illuminate low income homes (03/06/2014)

- Over 150 enterprises in Entech Hanoi 2014 (02/06/2014)

Devices

Energy Audit

ONLINE

(0909.901.045)

| MOU SIGNING CEREMONY ABOUT SPECIAL LED WITH COB TECHNOLOGY FOR FISHING SHIPS BETWEEN QUANG TRI PPC AND NEDO |