Top News

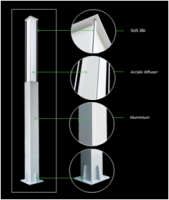

Mr. Nguyen Quan Chinh, Vice Chairman, People's Committee of Quang Tri Province came to visit the site of LED installation.

HRS showcase ultra-energy efficient biofertiliser pasteurisation technology

Pasteurisation is known to be an energy hungry process. To combat this the HRS system uses waste heat from the plant’s CHP engine via the engine’s cooling water and also recycles the heat (through heat exchanger tubes) used during the pasteurisation process to reduce energy consumption by up to 70%.

Helping operators to optimise the running of their plant, the system has been designed to run a continuous pasteurisation process even when digestate stocks fluctuate, plus the HRS supporting software package will track, trace and electronically report every batch of digestate back to the source/time/date/feedstock.

The system’s heat exchanger inner tube (which carries the digestate) is designed with a corrugated surface. This tube profile improves heat transfer and reduces digestate fouling, which can lead to equipment corrosion. Ultimately this innovation helps plant operators achieve a robust production process and exceptional OEE (overall equipment effectiveness), plus reduces equipment TCO (total cost of ownership).

Matt Hale, international sales manager at HRS Heat Exchangers commented: “Faced with increasing competition, falling gate fees, and degression, AD operators must optimise all aspects of their plant to achieve and demonstrate higher levels of efficiency. Not only will they benefit from the economics and carbon savings, their actions will help increase funder confidence. And for operators with crop based plants, it’s imperative that the right technology is implemented to help them make efficiency gains and meet the forthcoming Sustainability Criteria.”

Shortlisted for two ADBA 2015 awards*, the HRS 3 Tank Batch Sludge Pasteuriser System is already being used and commissioned at a number of UK AD plants including Veolia Environmental Services, The Shanks Group, Tamar Energy, UTS and Muntons.

Truong Duy

Source: tietkiemnangluong.com.vn

Newer articles

- Power Conservation Enhanced to Ensure Supply During the Dry Season (07/05/2015)

- Efficiency Standards for Commercial and Industrial Pumps Proposed (04/05/2015)

- Supreme Court to review U.S. electricity market efficiency rule (04/05/2015)

- Vietnam: Power for lighting doubles other countries' (04/05/2015)

- Energy labeling goes further in depth (01/05/2015)

Older articles

- ENERGY SAVER GUIDE (09/04/2015)

- 10 Energy Saving Tips for Spring (09/04/2015)

- Mobile port handling at BLG Logistics: energy-saving and flexible (06/04/2015)

- Automated Energy Saving with Wireless Lighting Control (06/04/2015)

- $100 Million For Solar PV Systems In Hawaii (06/04/2015)

Devices

Energy Audit

ONLINE

(0909.901.045)

| MOU SIGNING CEREMONY ABOUT SPECIAL LED WITH COB TECHNOLOGY FOR FISHING SHIPS BETWEEN QUANG TRI PPC AND NEDO |